The top-ofthe-range coping/profiler makes it easy to do 3D coping/profileing. These Robotic Coping & Profiling beams are reliable, as well as being able to cut saddles, chamlers, slots and other materials.

Owning our Robotic Coping and Profiling system is equivalent to an optimized fabrication process that has been automated specifically to bring ease to fabricators and metalwork manufacturers as it can easily work the processes of angle lines, beam drill lines, hydraulic punches, ironworkers, band saws and coping machines respectively. This is simply a way to take your fabrication processes from zero to a hundred!

Voortman CNC Beam Cambering features a rigid-steel C-frame, horizontal piston pusher, and memory settings that ensure reliable output for each project. The V2000 is operated by a simple touchscreen operator panel. Voortman’s V2000 Beam Camera & Straightening System produces consistent, reliable results every time.

All of your 3D coping and profiling is made easier with us using our top of the range coping and profiling robot. These Robotic Coping and Profiling beams are not only reliable but are designed for capacities which include cutting saddles, chamlers and slots respectively.

We make 3D coping, profiling and all other tasks easy with our top-ofthe-line coping/profiling robot. These Robotic Coping/Profiling beams have a high level of reliability and are capable of cutting slots, chamlers and saddles.

Gulf States Saw & Machine Co. uses a rigid steel C frame and horizontal pusher as well as memory settings for their Voortman CBN Cambering production. This ensures that all projects are delivered reliably. Voortman CNC Beam Cambering offers a simple touchscreen operator panel.

Give us a call and we'll assist in finding the most suitable, cost-effective fabricating equipment for your needs.

Voortman CNC Beam Cambering features rigid-steel frames, horizontal piston pushers, memory settings, and reliable outputs for all projects. It is controlled via a user-friendly touchscreen panel.

If you have any questions about the quality of our Robotic-coping and profiling machines, we can tell you that they have passed the most important fabrication tests, including hardness and surface texture, beam access hole quality, beam flange welding access hole hole quality, bolt hole size, positioning, and perpendicularity. We have, as always, made available the Voortman CNC coping and profiling machines through our stocking. This machine is built to an exceptional standard, and has outstanding capabilities.

Voortman CNC beam Cambering has a steel Cframe and a horizontal Cylinder pusher. There are also memory settings. This ensures consistent output for every project. The V2000 can be operated easily via the touchscreen operator panel.

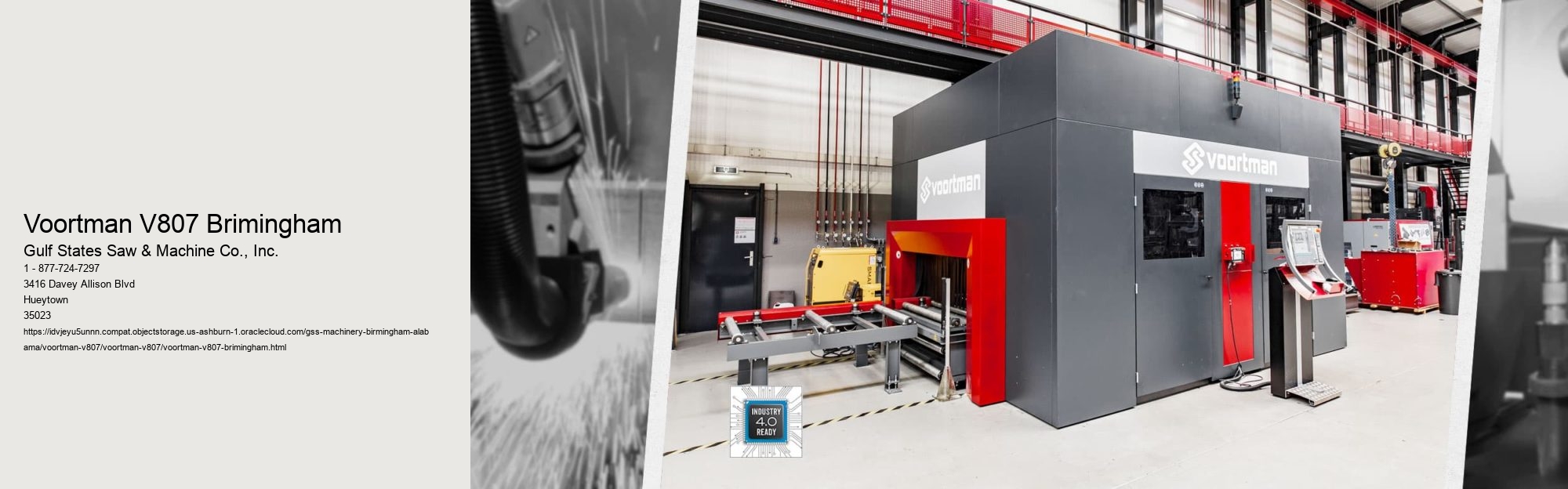

Voortman Steel Machinery proudly announces the VoortmanV807 robotic thermal profiling machine. It is capable of plasma cutting and oxyfuel cutting at a faster rate than other robotic profiling machines on the marketplace. The V808 profile processing machine was an enormous success. Now, the V807 has been developed using years of research, development, and experience to significantly reduce the machine's footprint while enhancing its superior capabilities and performance.

BENEFITS INVOLVED: Smart cambering and accurate, automated positioning, Hydraulic pusher, PLC controller, Remote control mobility, Combine cambering of other Voortman devices

We care about making fabrication tasks smooth and efficient. Our Robotic coping/profiler beam can handle both angles bars, channels and square tubes. However, it can also process pipes, T-bars, plates, bulbs and even plates. Because it is an efficient tooling platform, our Coping/Profiling Robots offer endless possibilities in terms of how they can be used to cut your pipes/profiles. These outputs are H, I andT beams as well as U and/or L channels.

Voortman CNC Beam Cambering features an aluminum C frame, horizontal piston pusher, as well as memory settings. This allows for reliable output on all projects. It has a touchscreen operator panel, making it extremely easy to operate the V2000.

Coping is a process that allows a beam to fit into other parts of a framework.

Three types There are two types: simply supported and roller support. Pinned support, hinged support.

Factors that Improve Coping: There are three important factors that can influence coping: Social support, optimism, control, and perception. Many studies have shown that good social support is associated with better mental and physical health.

WHAT IS COPE DATA? C. O.P. E. stands for Construction. Occupancy. Protection. Exposure. This data shows the probability that an organization will suffer losses from a catastrophic event.